All results 6568

Downloads

Downloads

Downloads

Downloads

Downloads

Downloads

Downloads

Downloads

Downloads

Downloads

Downloads

Downloads

Downloads

Downloads

Downloads

Downloads

Downloads

Downloads

Downloads

Downloads

Downloads

Downloads

Downloads

Downloads

Downloads

Downloads

Downloads

Downloads

Downloads

Downloads

Downloads

Downloads

Downloads

Downloads

Downloads

Downloads

Downloads

Downloads

Downloads

Downloads

Downloads

Downloads

Downloads

Downloads

Downloads

Downloads

Downloads

Downloads

Downloads

Downloads

Downloads

Downloads

Downloads

Downloads

Downloads

Downloads

Downloads

Downloads

Downloads

Downloads

Downloads

Downloads

Downloads

Downloads

Downloads

Downloads

Downloads

Downloads

Downloads

Downloads

Downloads

Downloads

Downloads

Downloads

Downloads

Downloads

Downloads

Downloads

Downloads

Downloads

Downloads

Downloads

Downloads

Downloads

Downloads

Downloads

Downloads

Downloads

Downloads

Downloads

Downloads

Downloads

Downloads

Downloads

Downloads

Downloads

Downloads

Downloads

Downloads

Downloads

Downloads

Downloads

Downloads

Downloads

Downloads

Downloads

Downloads

Downloads

Downloads

Downloads

Downloads

Downloads

Downloads

Downloads

Downloads

Downloads

Downloads

Downloads

Downloads

Downloads

Downloads

Downloads

Downloads

Downloads

Downloads

Downloads

Downloads

Downloads

Downloads

Downloads

Downloads

Downloads

Downloads

Downloads

Downloads

Downloads

Downloads

Downloads

Downloads

Downloads

Downloads

Downloads

Downloads

Downloads

Downloads

Downloads

Downloads

Downloads

Downloads

Downloads

Downloads

Downloads

Downloads

Downloads

Downloads

Downloads

Downloads

Downloads

Downloads

Downloads

Downloads

Downloads

Downloads

Downloads

Downloads

Downloads

Downloads

Downloads

Downloads

Downloads

Downloads

Downloads

News

15.11.2023

CORALINK, AUMA’s digital ecosystem, is the winner of this year’s Primus Award in the actuators category.

To the news

News

15.07.2024

Under the motto “Fit for the digital future” AUMA is enhancing its range of service offerings for upgrading existing plants with state-of-the-art, high-performance valve actuation technology.

To the news

News

17.10.2024

AUMA is celebrating its 60th anniversary this year. In September, the company invited employees, families and friends to a big anniversary celebration at its headquarters in Müllheim, Germany.

To the news

News

11.12.2024

AUMA’s TIGRON has been honoured as best actuator of the year and the winner of this year’s Valve Stars Award in the Actuator category.

To the news

News

16.01.2025

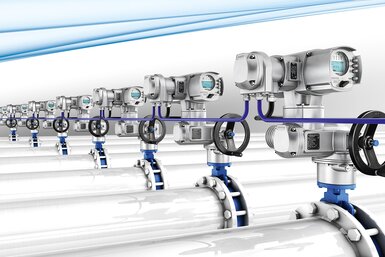

241 AUMA electric actuators have been installed as part of a retrofit at Stockholm’s largest combined heat and power plant, Kraftvärmeverk 1.

To the news.eec392c3.jpg)

News

29.02.2024

AUMA has added an explosion-proof version to its successful PROFOX actuator series.

To the news

News

09.01.2024

AUMA hosted a two-day conference on functional safety at its headquarters in Muellheim, Germany, at the end of November 2023.

To the news

News

03.07.2025

As partner of the KROHNE Academy, we invite you to Duisburg on 16 and 17 September 2025 for a free seminar on "Optimization of Safety Loops acc. to IEC 61508/61511".

To the news

Product

AC (with display)

AC actuator controls are your perfect solution if the application requires self-adapting control functions, data logging, a configurable interface or if valve and actuator are to be integrated into a Plant Asset Management System due to advanced diagnostic functions.

AC actuator controls are equipped with a parallel interface for free configuration and/or interfaces to fieldbus systems as used within process automation.

The diagnostic functions comprise a time-stamped event report, torque characteristics logging, continuous recording of temperatures and vibration within the actuator and, furthermore, counting the number of starts and motor running times.

Further to the basic functions, AC actuator controls offer a number of options to meet special demands. These include torque bypass to unseat valves if tightly seated or functions for extending operating times to avoid water hammer within pipelines.

With the development of the AC 01.2, particular emphasis was laid on user-friendliness and the ease of integration of actuators into the DCS. The large graphic display is used to perform menu-controlled programming of the actuator controls, optionally using AUMA CDT via wireless Bluetooth connection. For fieldbus connections, AC programming can be performed from the control room.

To the product

Product

Part-turn actuators

With the FQM fail safe unit, AUMA offers innovative and safe actuator solutions for automatic operation of valves in case of emergencies making use of stored mechanical energy.

Constant torque characteristics across the overall torque range.

The spring is not operated during standard operation. As a consequence, actuator sizing can be relatively small.

The end position switches are automatically set during the setting procedure of end positions OPEN and CLOSED and do not require separate adjustment.

To the product

Product

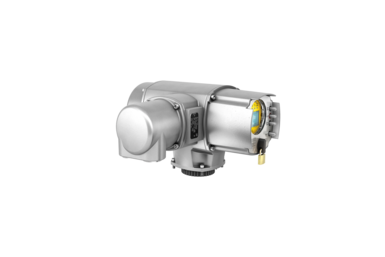

Multi-turn actuators

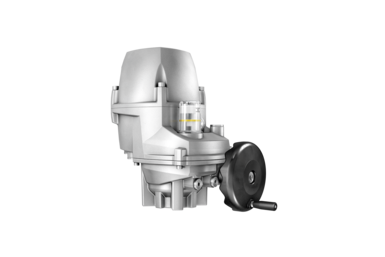

One solution for gate, butterfly, ball/plug and globe valves. Compact actuators with intelligent functions as platform concept for tailored automation solutions.

Each PROFOX is equipped with a centrally located LED: The FOX-EYE. It provides clearly visible information about both actuator and valve status. The FOX-EYE display scheme can be configured by the user as required.

To the product

Product

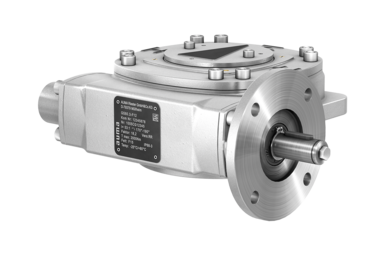

Part-turn gearboxes

AUMA part-turn gearboxes are used for operating part-turn and special valves (damper, flue gas damper, ball valves).

Product

Communication systems

Many different fieldbus systems are available on the market. Certain preferences have evolved on a regional level or specifically to certain plant applications. Since AUMA actuators are implemented in all types of technical process plants around the globe, they are available with interfaces for the different established fieldbus systems within the process automation industry.

Overall, AUMA devices are available with digital and analogue inputs to connect additional sensors to the fieldbus.

To the product

Product

Linear actuators

Electric linear actuators performing a linear movement for automating globe valves, for example, can be combinations of SA multi-turn actuators and LE linear thrust units. If a lever arrangement has to be operated, the LE linear trust unit can also be mounted onto a base.

To the product

Product

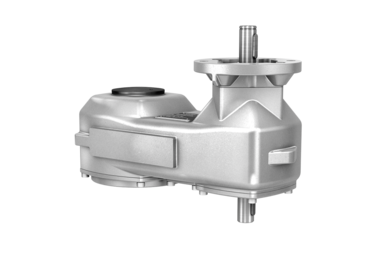

Multi-turn gearboxes

If the drive shaft is to be positioned at a certain angle to the output drive shaft, combinations of the SA multi-turn actuators with GST spur gearboxes are used.

The output torque can be considerably multiplied.

To the product

Product

AC (with display)

Explosion-proof devices must be used in plants where potentially explosive atmospheres are likely to occur. These devices are designed so that they will not act as an ignition source. They neither generate ignition sparks, nor hot surface temperatures. Certification is performed in close collaboration with national and international certification bodies. For multi-turn actuators SAEx/SAREx 07.2 – SAEx/SAREx 16.2 and part-turn actuators SQEx/SQREx 05.2 – SQEx/SQREx 14.2, AUMATIC ACExC 01.2 actuator controls with integral local controls are available.

To the product

Product

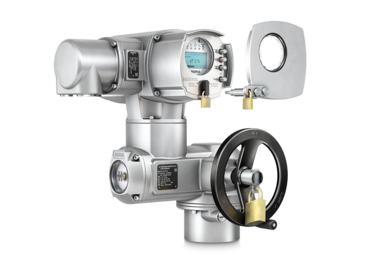

Accessories

The lockable protection covers and lock kits prevent unauthorised operation of actuator controls or handwheels.

Product

Linear thrust unit

Electric linear actuators performing a linear movement for automating globe valves, for example, can be combinations of SA multi-turn actuators and LE linear thrust units. If a lever arrangement has to be operated, the LE linear trust unit can also be mounted onto a base.

To the product

Product

AM (without display)

AM actuator controls with their straightforward design are the perfect choice when using parallel signal transmission while a relatively low number of feedback signals is required. Few parameters need to be defined via sliding switches during commissioning, e.g. type of seating in end positions. Control is made via operation commands OPEN, STOP, CLOSE. Reaching an end position and collective fault signals are reported back to the DCS as feedback signals. These signals are visually displayed at the local controls via the indication lights. As an option, the valve position can be transmitted as 0/4 – 20 mA signal to the DCS.

To the product

Product

AM (without display)

Explosion-proof devices must be used in plants where potentially explosive atmospheres are likely to occur. These devices are designed so that they will not act as an ignition source. They neither generate ignition sparks, nor hot surface temperatures. Certification is performed in close collaboration with national and international certification bodies. For multi-turn actuators SAEx/SAREx 07.2 – SAEx/SAREx 16.2 and part-turn actuators SQEx/SQREx 05.2 – SQEx/SQREx 14.2, AUMA MATIC AMExC 01.1 actuator controls with integral local controls are available.

To the product

Product

Multi-turn actuators

A sophisticated sealing system combined with excellent corrosion protection properties qualify AUMA actuators for underwater use.

Double sealed cable glands at the particularly crucial electrical connection safely prevent any ingress of water. Inner seals at all housing covers, sometimes coming in pairs, as well as a solid shaft made of stainless steel complete the universal concept.

To the product

Product

Multi-turn actuators

A sophisticated sealing system combined with excellent corrosion protection properties qualify AUMA actuators for underwater use.

Double sealed cable glands at the particularly crucial electrical connection safely prevent any ingress of water. Inner seals at all housing covers, sometimes coming in pairs, as well as a solid shaft made of stainless steel complete the universal concept.

To the product

Product

Multi-turn actuators

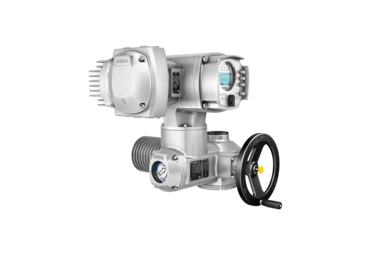

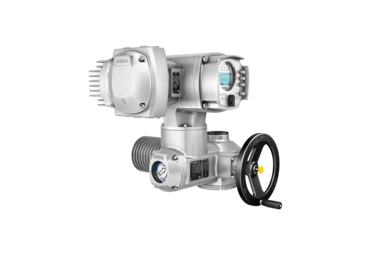

The TIGRON is a multi-turn actuator with classic mission: Automation of gate valves with/without rising stem, of globe valves (double block and bleed valves) and in combination with part-turn gearbox of butterfly valves and ball valves.

Virtually unlimited stroke

Rising stems are led through the hollow shaft of the multi-turn actuator which drives the stem in combination with the output drive type A. The stem protection tube protects the stem from pollution and people from injuries.

Open-close duty, positioning duty and modulating duty

TIGRON actuator versions are available for all types of duty. Combinations with multi-turn gearboxes In combination with GK or GST gearboxes, torques up to 16,000 Nm can be reached.

Modular AUMA scheme

Six gearbox type ranges are part of AUMA’s product portfolio. They are ideally suited to complete and enhance TIGRON’s application range even to other valve designs. This includes numerous butterfly valves or the conventional ball valves of the oil and gas industry requiring a part-turn movement of mostly 90 degrees. In these cases, TIGRON is combined with AUMA part-turn gearboxes.

AUMA linear thrust units convert TIGRON’s multi-turn movement into a thrust movement which is required for globe valve automation.

To the product

Product

Multi-turn actuators

With SAVEx .2 multi-turn actuators for open-close duty paired with intelligent ACVExC 01.2 actuator controls, the proven AUMA SAEx/SAREx range is enhanced by variable speed models.

SAVEx multi-turn actuators are rated for open-close duty and positioning duty (classes A and B) / (short-time duty S2 - 15 min). Special sizing for longer running times is available for the S2 - 30 min duty.

To the product

Product

Multi-turn actuators

With SARVEx .2 multi-turn actuators for modulating duty paired with intelligent ACVExC 01.2 actuator controls, the proven SAEx/SAREx range is enhanced by variable speed models.

SARVEx multi-turn actuators are rated for modulating duty (class C) S4 - 25 %. Special versions for S4 - 50 % are also available.

To the product

Product

Part-turn actuators

When combining SA multi-turn actuators with GS part-turn gearboxes, the combination acts as electric part-turn actuator fulfilling higher torque requirements.

Thus, these combinations represent a complement to the SQ part-turn actuators with their 2,400 Nm torque range limit.

To the product

Product

AC (with display)

AUMA offers sophisticated control for premium safety requirements with AC 01.2-SIL or ACExC 01.2-SIL actuators controls. SA .2 and SQ .2 actuators combined with these actuator controls can be deployed in safety-related system systems up to SIL 3. AC 01.2 actuator controls in SIL version are equipped with an additional SIL module designed for the execution of safety functions. In case of an emergency at the plant and when requesting a safety function, the standard logic of AC is bypassed and the safety function is performed via the safe SIL module. Consequently, the safety function always overrules standard operation. SA .2 and SQ .2 actuators equipped with these actuator controls have been certified by TÜV Nord. They are suitable for the following safety functions: