All results 2654

Product

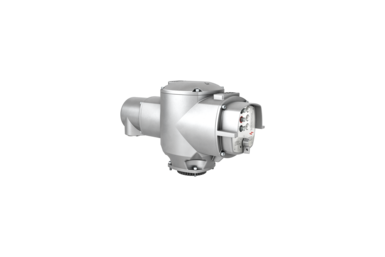

AC (with display)

AC actuator controls are your perfect solution if the application requires self-adapting control functions, data logging, a configurable interface or if valve and actuator are to be integrated into a Plant Asset Management System due to advanced diagnostic functions.

AC actuator controls are equipped with a parallel interface for free configuration and/or interfaces to fieldbus systems as used within process automation.

The diagnostic functions comprise a time-stamped event report, torque characteristics logging, continuous recording of temperatures and vibration within the actuator and, furthermore, counting the number of starts and motor running times.

Further to the basic functions, AC actuator controls offer a number of options to meet special demands. These include torque bypass to unseat valves if tightly seated or functions for extending operating times to avoid water hammer within pipelines.

With the development of the AC 01.2, particular emphasis was laid on user-friendliness and the ease of integration of actuators into the DCS. The large graphic display is used to perform menu-controlled programming of the actuator controls, optionally using AUMA CDT via wireless Bluetooth connection. For fieldbus connections, AC programming can be performed from the control room.

To the product

Product

AM (without display)

AM actuator controls with their straightforward design are the perfect choice when using parallel signal transmission while a relatively low number of feedback signals is required. Few parameters need to be defined via sliding switches during commissioning, e.g. type of seating in end positions. Control is made via operation commands OPEN, STOP, CLOSE. Reaching an end position and collective fault signals are reported back to the DCS as feedback signals. These signals are visually displayed at the local controls via the indication lights. As an option, the valve position can be transmitted as 0/4 – 20 mA signal to the DCS.

To the product

Product

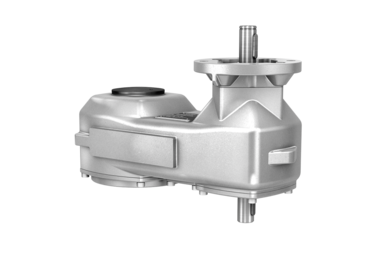

Multi-turn gearboxes

If the drive shaft is to be positioned at a certain angle to the output drive shaft, combinations of the SA multi-turn actuators with GST spur gearboxes are used.

The output torque can be considerably multiplied.

To the product

Product

Part-turn gearboxes

AUMA part-turn gearboxes are used for operating part-turn and special valves (damper, flue gas damper, ball valves).

Product

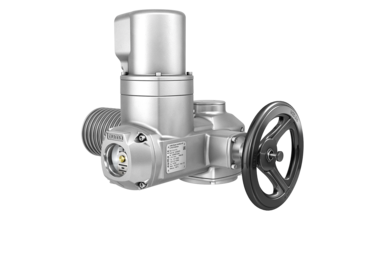

Multi-turn actuators

If the drive shaft is to be positioned at a certain angle to the output drive shaft, combinations of the SA multi-turn actuators with GST spur gearboxes are used. The output torque can be considerably multiplied.

To the product

Product

Multi-turn actuators

A sophisticated sealing system combined with excellent corrosion protection properties qualify AUMA actuators for underwater use.

Double sealed cable glands at the particularly crucial electrical connection safely prevent any ingress of water. Inner seals at all housing covers, sometimes coming in pairs, as well as a solid shaft made of stainless steel complete the universal concept.

To the product

Product

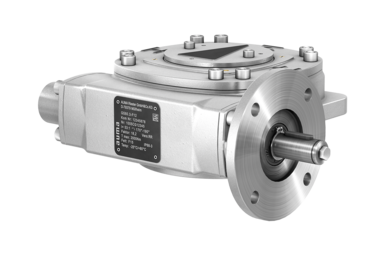

Multi-turn actuators

If the effective direction must be displaced by 90°, combinations of multi-turn actuators SA 07.2 – SA 16.2 / SA 25.1 – SA 48.1 and GK bevel gearboxes are used.

The output torque can be considerably multiplied.

To the product

Product

Multi-turn actuators

The SAI/SARI type range is designed for the automation of valves in nuclear power plants. SAI/SARI actuators are used inside containment and are qualified in compliance with IEEE 382-2006. The DBE resistant SAI/SARI actuators can take over safety functions under DBE conditions. Multi-turn actuators of SAI type range can be used for open-close duty and positioning duty. SARI actuators are designed for modulating duty.

To the product

Product

Multi-turn actuators

The use of a frequency converter specially conceived for the actuator deployment offers many advantages. Besides the variable speed, the insensitivity to voltage and frequency variations, the lack of current increase during motor start-up as well as the valve protection by soft approaching of the end positions should be mentioned.

The rugged design makes these actuators extremely resistant to environmental impacts (standard corrosivity category C5, IP67, double sealed - enclosure protection is also ensured during commissioning) and can be further enhanced as an option.

The SEVEN actuator is available in three electronic variants: ECOTRON, PROFITRON and HiMod.

To the product

Product

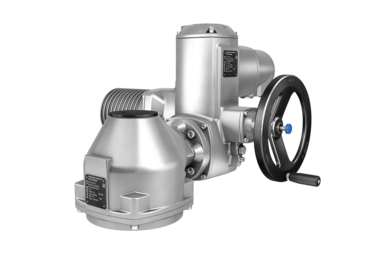

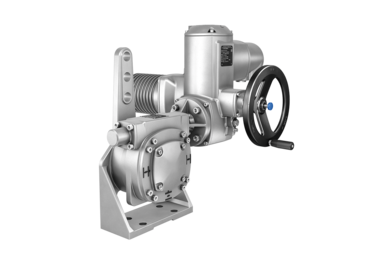

Part-turn gearboxes

Part-turn actuators with base and lever offer consequently an ideal solution if valves like butterfly valves can only be operated using a lever arrangement, due to space constraints.

In case of higher torque requirement, SA multi-turn actuators are combined with a part-turn gearbox with base and lever. The gearboxes are based on GS part-turn gearboxes which are converted by the combination with base and lever. Since this can be fitted retrospectively, benefits in warehousing are obvious.

To the product